The Infinium Wall

At almost 300 feet long, this structure was the highlight of the third floor and shared the CBOT’s history through imagery and technology.

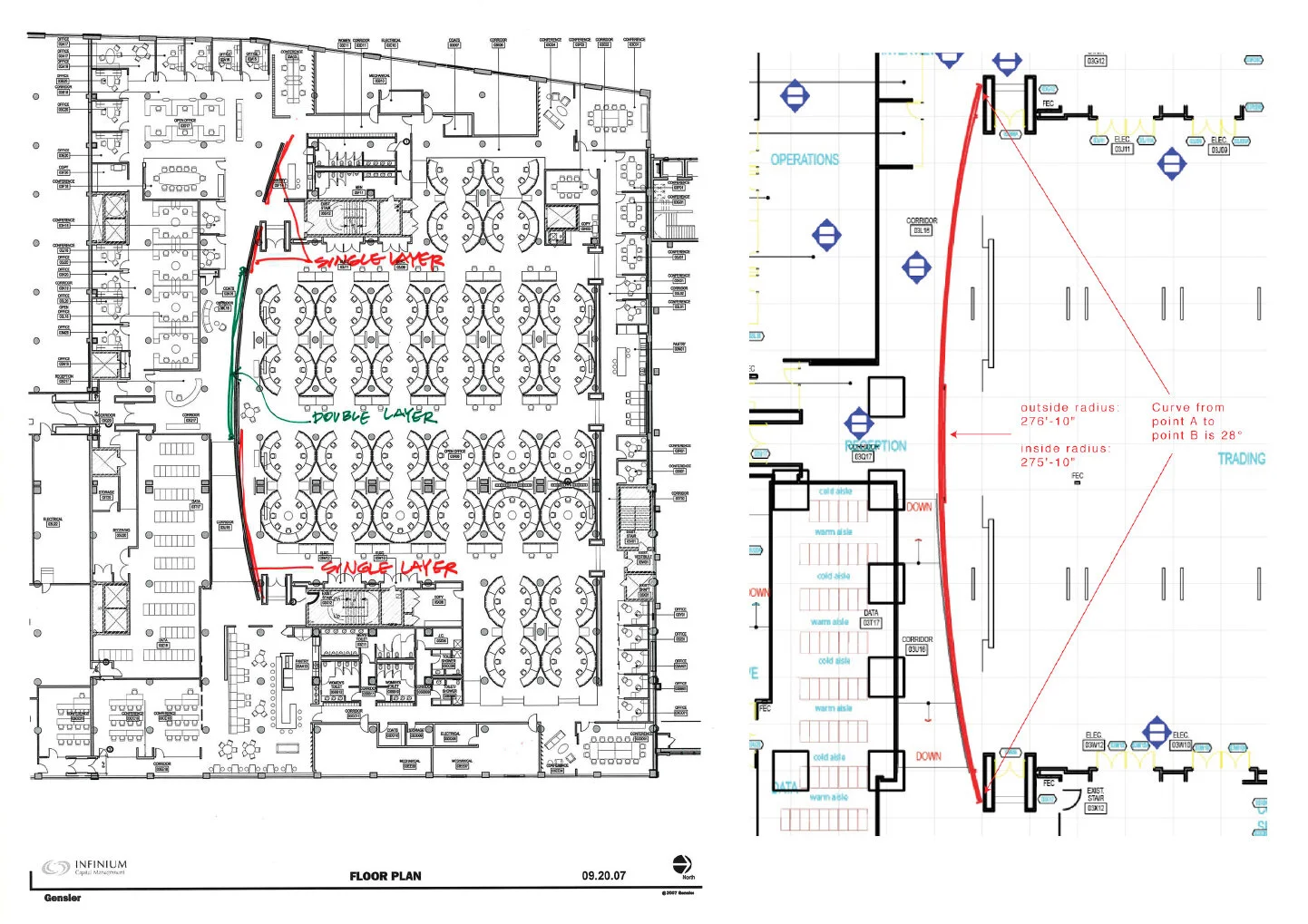

In 2007, Gensler contracted Skyline Metro Chicago to develop a wall system for their client, Infinium Capital Management, a Chicago-based trading firm. It’s purpose was to separate the high-speed trading area from the lobby and other common areas. It not only had to be attractive and tell the story of the CBOT, it required security features and interactive components as well.

A blank canvas set in the Historical Montgomery Ward Building, there were several existing factors to consider before even sketching out initial concepts. Various utility lines, support columns and varying slopes of the ceiling and floor made construction a challenge.

This being a newly constructed space, my work and Gensler's work developed in tandum because of the project deadline. Instead of building around existing structures, we were forced to go in blind and work only from the provided floorplan.

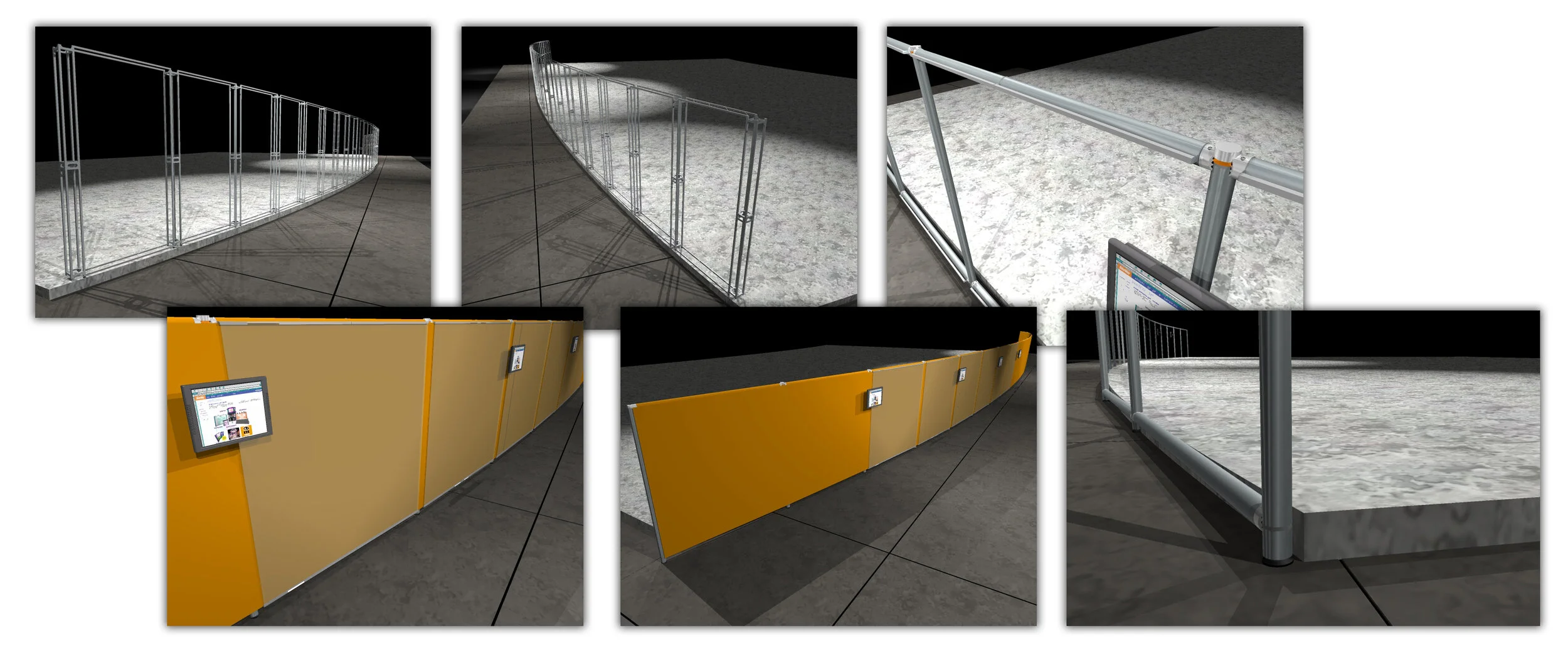

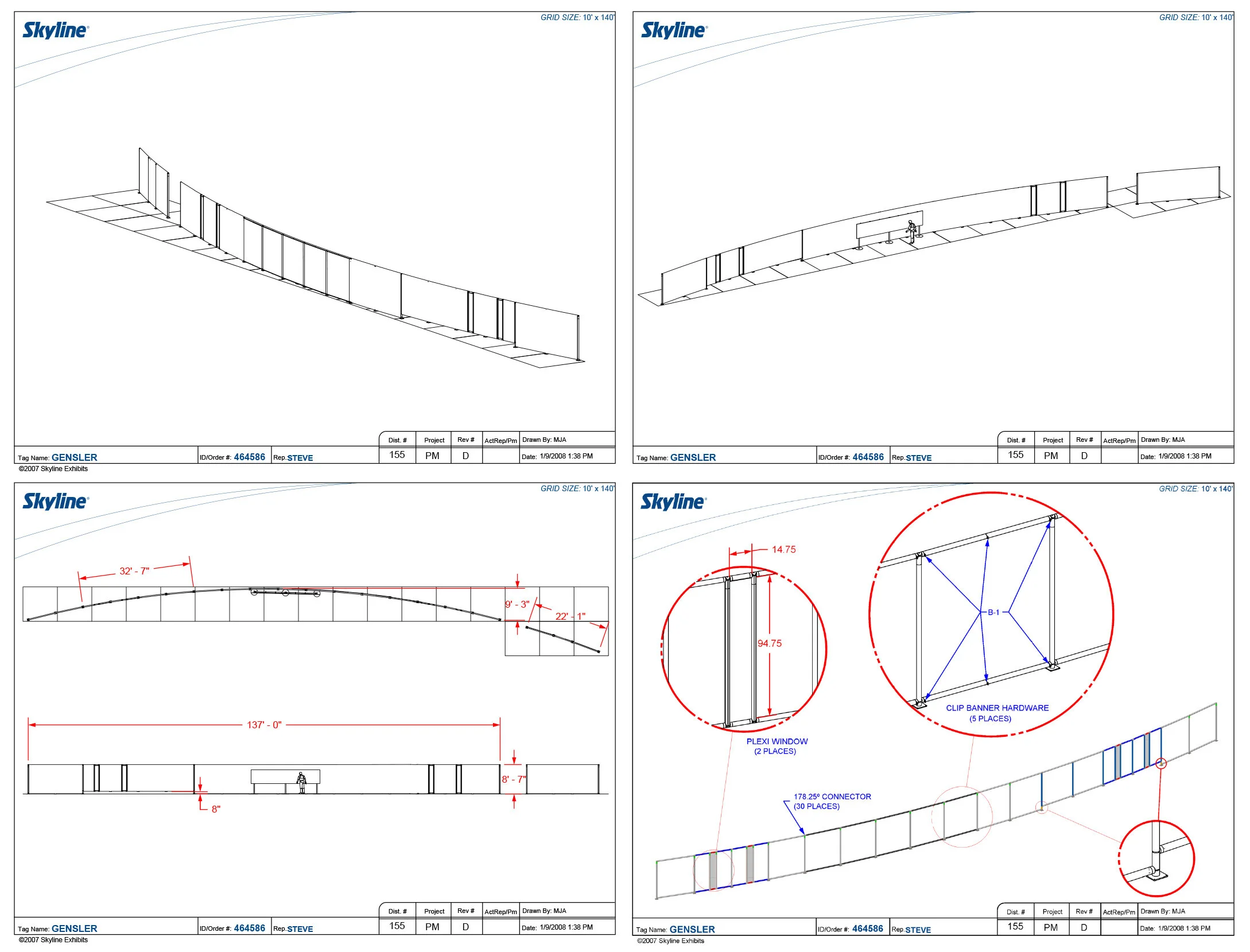

After all criteria was communicated, I began my structural concepts. We quickly discovered that our heavy duty Tube System was best suited for this project. It was a sturdy, modular extrusion able to hold substantial weight.

Th client wanted the ability to incorporate AV into the wall structure. We proposed adding sections of sheer tension fabric and projecting live news programming or company announcements. When it wasn't needed, the sheer panel could be easily removed.

When the concept was approved, a structural CAD was created by our engineering department. I worked closely with the Project Manager and CAD team to revise the drawings as necessary to meet the client requirements. Graphic Design concepts were happening simultaneously as the structure was being finalized...

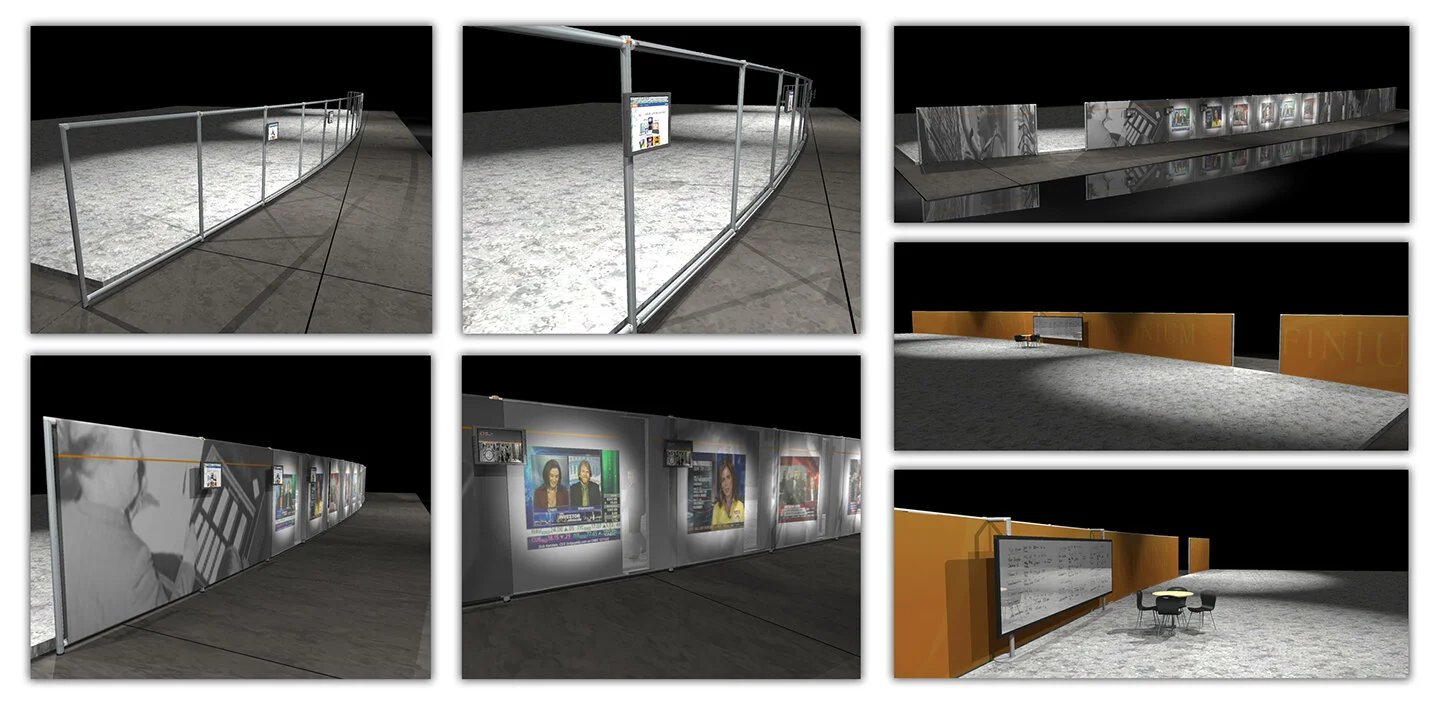

The idea was to create a photographic "timeline" showing the progress and advancement of the CBOT through technology. However, many stock images, like the ones above, are Rights Managed and very expensive. Ultimately, we had to take matters into our own hands...

After a lot of red tape and paperwork, I was permitted to be escorted down to the trading floor of the CBOT. As soon as the bell rung, silence turned to chaos. I took as many pictures as I possibly could. Above are a few images I captured and incorporated into the wall design.

After several structural and graphics revisions, above is a 2D mock up of the final approved layout. The front, or common area side, was to show the progress and advancement in trading over the years and ICM's growth and evolution into the industry. The back, or trading area side, was to act as a clean and attractive backdrop to the 20 foot long white board that was incorporated into the project.

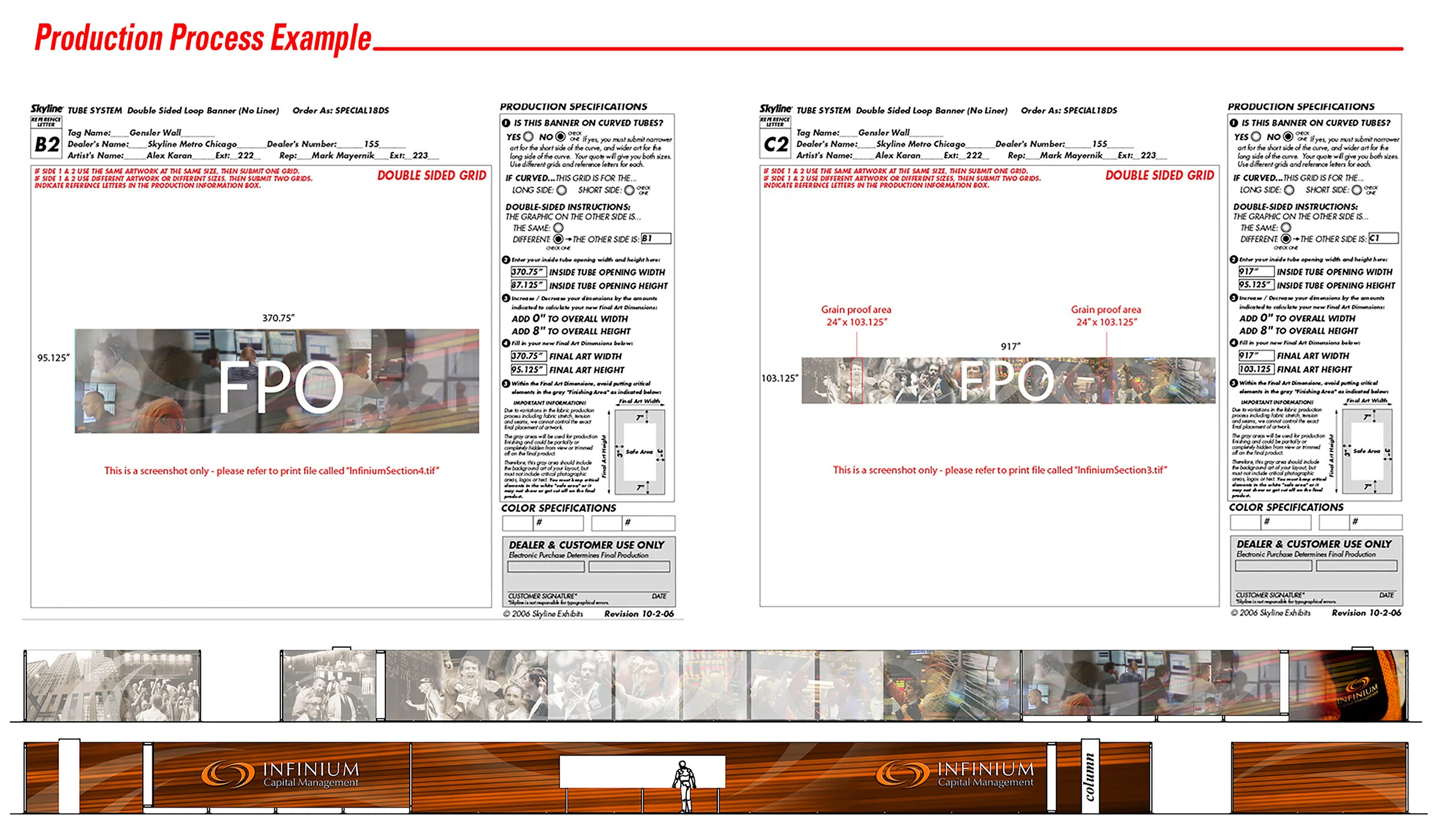

After images were selected and a layout was completed and approved, the Production process begins. Above is an example of the templates that were created for all the tension fabric graphics that wrapped around the tube system.

Production files were then sent to our International Design Center in Eagan, MN where printing, stitching and fabrication takes place. I supervised the staging of the structure at IDC and approved all setup and graphics prior to shipping to the client destination. The following slides show the final product in it's home prior to the grand opening of the new space...